Product Description

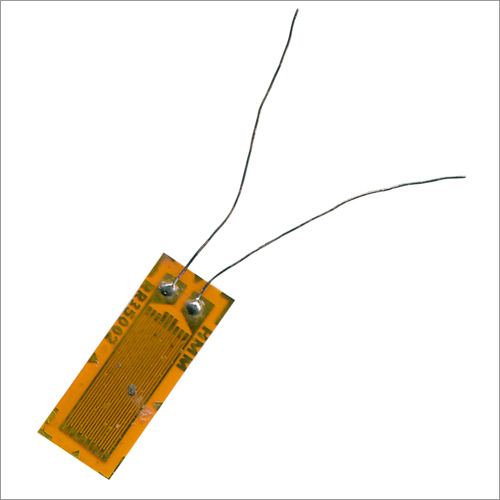

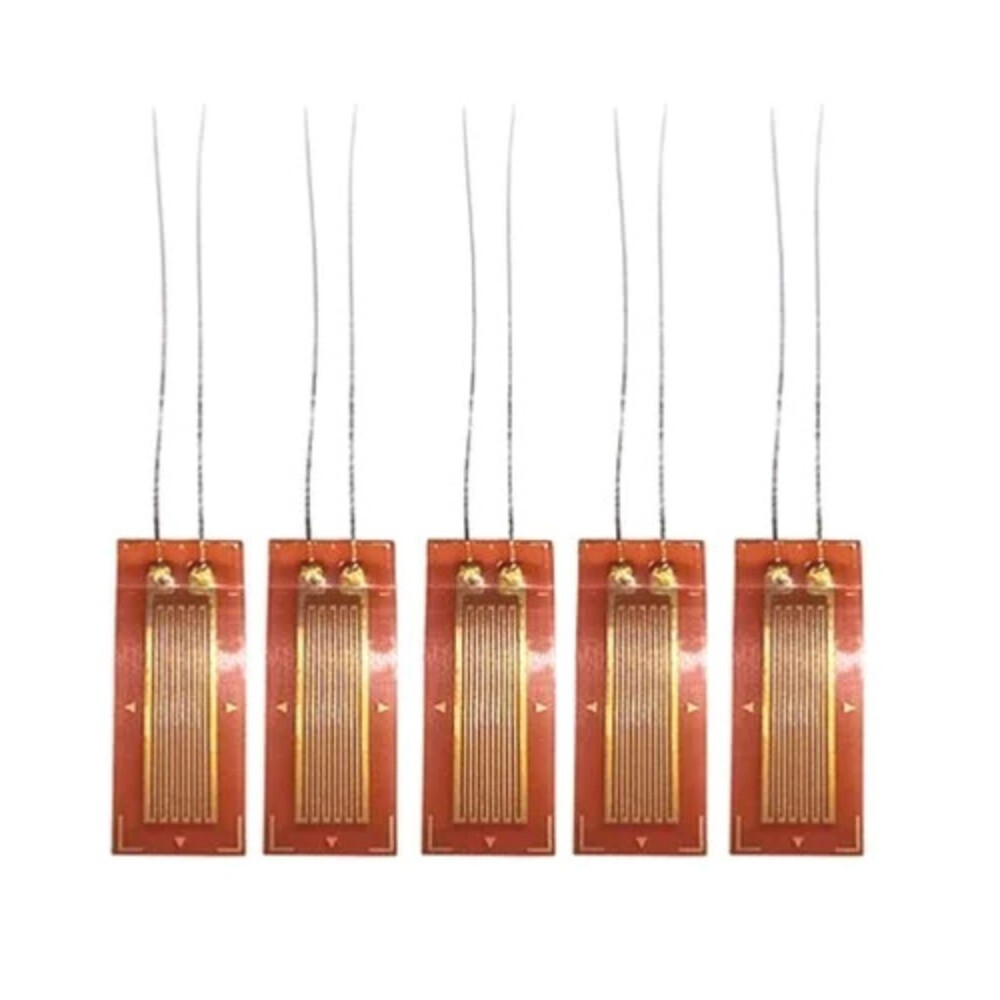

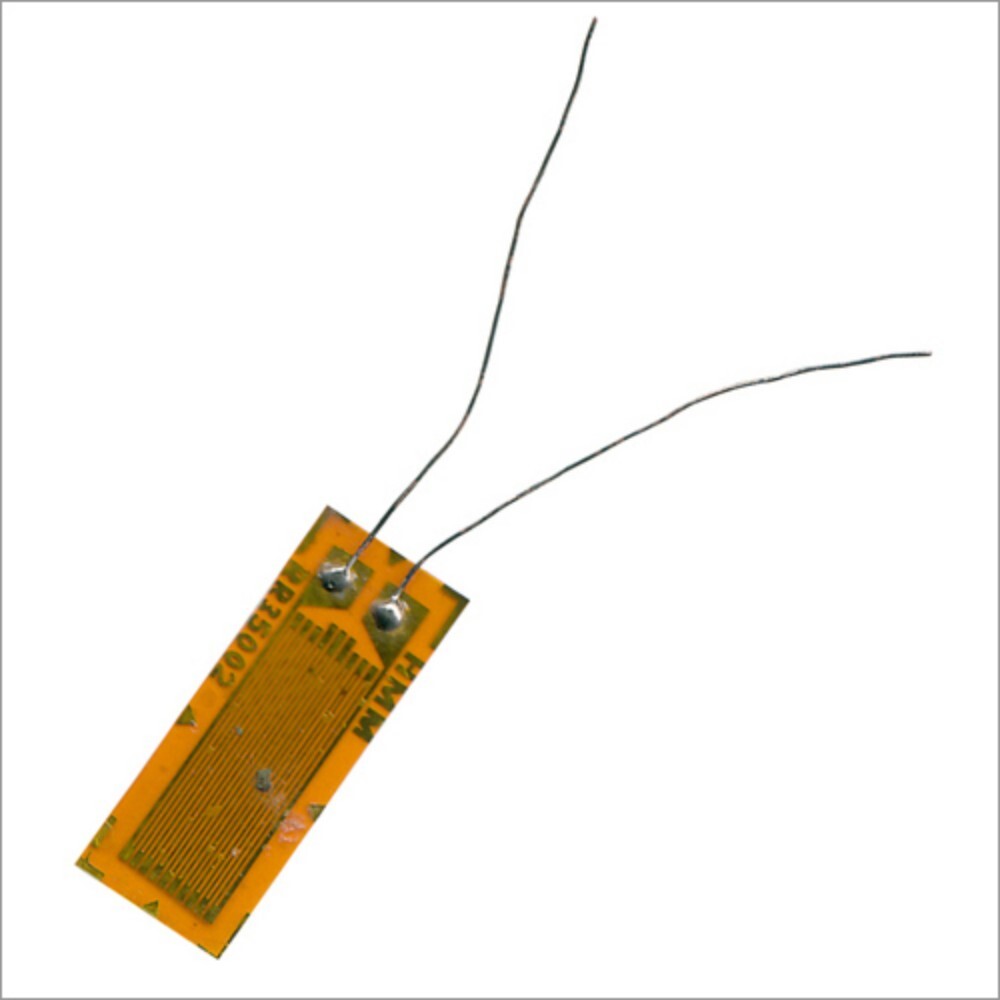

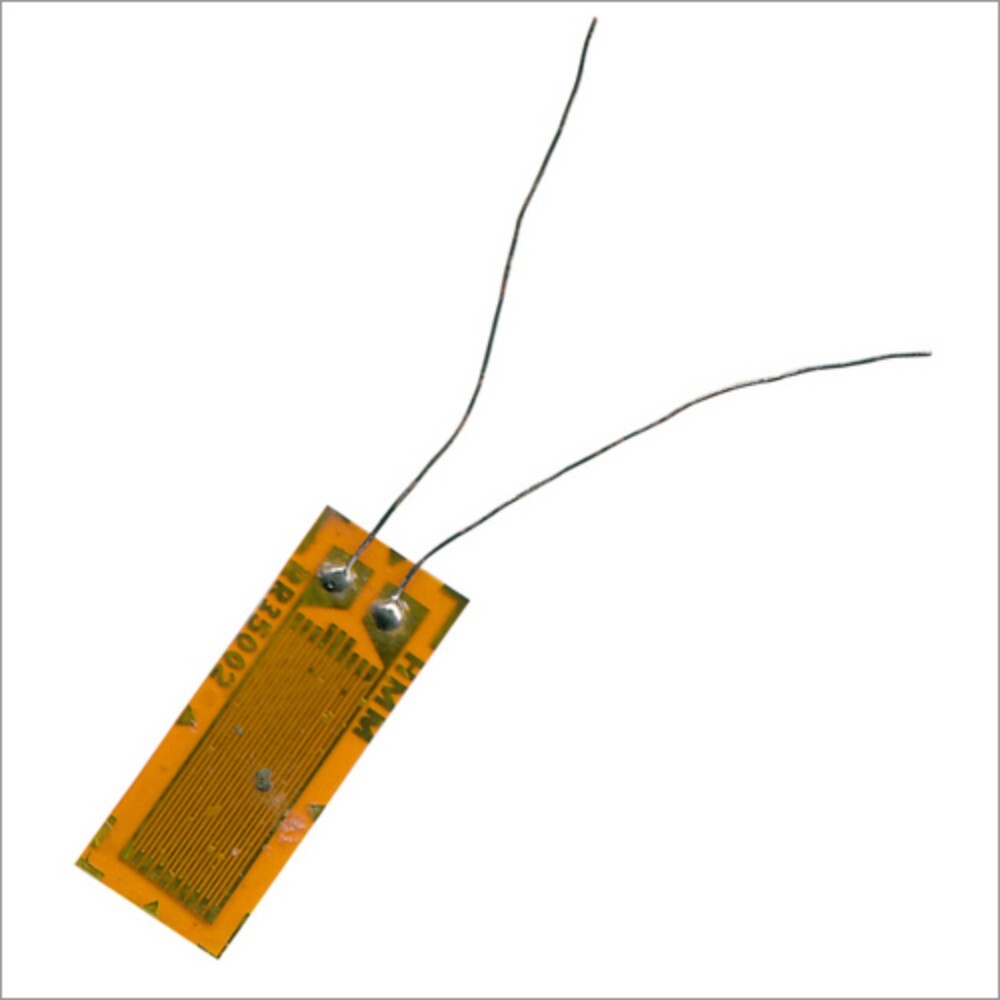

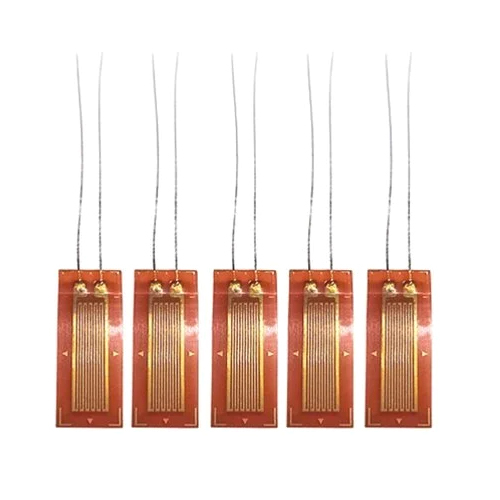

Foil Type Gauges and Accessories:

- Foil type strain gauges both standard linear, patterns and rosettes.

- Diaphragm gauges for pressure transducers.

- Adhesives for strain gauge installation.

- Accessories such as terminal tabs, lead wires etc.

- Gauging Services etc.

Consultation available on the following:

- Determination of suitable measuring points.

- Assistance in selection of appropriate Strain Gauge.

- Precise bonding for torsion, bending, tractive force and pressure measurements.

- Bonding with full, half and quarter bridges.

- Precise multiple bonding to increase measuring accuracy.

- Temperature, bending, and centrifugal force compensation.

Technical Specification :

|

Type

|

Foil

|

|

Resistance

|

120 Ohms

350 Ohms

|

|

Grid Length

|

1 to 10 (MM)

|

|

Material

|

Constantan

|

|

Temperature Limit (Static)

|

-1500 C to 1000 C

|

|

Gauge Factor (Nominal)

|

2.1

|

|

Elongation

|

5% (Maximum)

|

|

Lead Wire (Size)

|

25 MM Optional

|

|

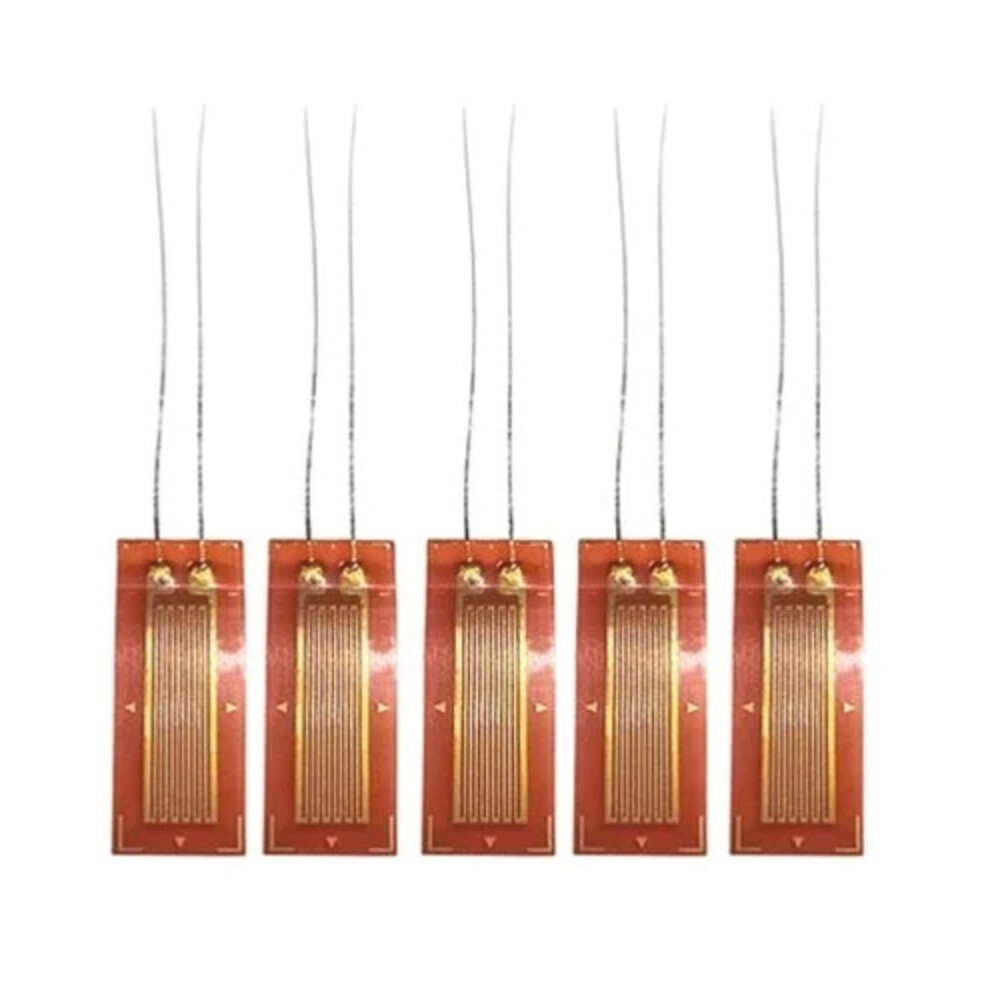

Packing

|

5 Gauges in 1 Packet

|

Strain Gauges for Stress and Strain Measurement :

The basic function of a strain gauge is to measure strain, and in turn stress. Strain is simply the change in length of a component divided by the original length of the component while experiencing an applied load. Stress is calculated by multiplying the strain by the modulus of elasticity for the specific material being measured.

Strain Gauges for Load Measurement :

Strain gauges are integral elements of load cell transducers, which measure the magnitude of an applied tensile or compressive force. The strain gauges are installed on precisely machined spring elements where the exact cross section is known, and therefore the strain measurement can be converted to a load measurement output.

Strain Gauges for Pressure Measurement :

A pressure sensor uses a full bridge strain gauge configuration. The sensor measures the applied pressure over a discrete area.

Strain Gauges for Torsion Measurement :

Strain gauges are used to measure the torsion forces in a rotating shaft to ensure that the shaft is not being overloaded. Shaft overload can lead to fatigue over time or fracture, resulting in a system failure.

Shear Strain Measurement :

Two single axis strain gauges or a two element 900 Rosette can be mounted at 900 to convert shear strain to shear stress.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese